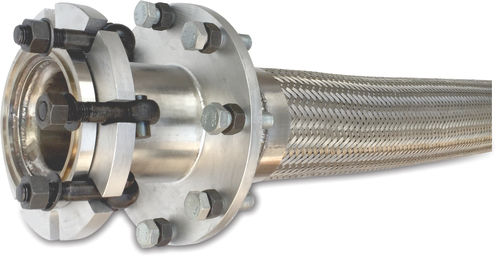

Stainless Steel Hose

Product Details:

- Medium Steam, Water, Oil, Gas

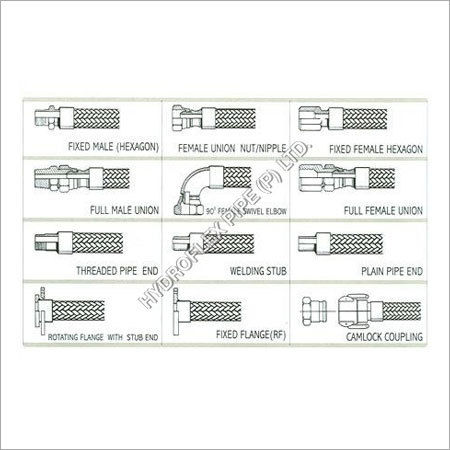

- Connection Type Flanged / Threaded / Camlock

- Reinforcement Stainless Steel Braid

- Shape Flexible Corrugated Hose

- Cover Stainless Steel

- Hardness 30-90 Shore A

- Material Stainless Steel (AISI 304/316)

- Click to View more

Stainless Steel Hose Price And Quantity

- 300.00 - 1000.00 INR/Piece

- 100 Piece

- Natural Stainless Steel

- Yes

- Excellent

- Varies per size

- Custom lengths available

- BS 6501 / EN ISO 10380

- SS 304/316, Brass, Carbon Steel

- Industrial, Chemical, Petrochemical, HVAC, Food & Pharma

- Annular Corrugated

- Excellent

- Up to 860 bar

- High

Stainless Steel Hose Product Specifications

- -40C to +600C

- 6 mm to 300 mm

- Steam, Water, Oil, Gas

- Flexible Corrugated Hose

- Stainless Steel

- Stainless Steel (AISI 304/316)

- 30-90 Shore A

- Flanged / Threaded / Camlock

- 8 mm to 320 mm

- Stainless Steel Braid

- Up to 215 bar

- Natural Stainless Steel

- Yes

- Excellent

- Varies per size

- Custom lengths available

- BS 6501 / EN ISO 10380

- SS 304/316, Brass, Carbon Steel

- Industrial, Chemical, Petrochemical, HVAC, Food & Pharma

- Annular Corrugated

- Excellent

- Up to 860 bar

- High

Stainless Steel Hose Trade Information

- 1000 Piece Per Day

- 1 Days

Product Description

Owing to our specialization in this domain, we are engaged in manufacturing and supplying supreme quality Stainless Steel Hose. Manufactured by utilizing premium quality stainless steel in tune with predefined industry standards, this is made available in various dimensions and shapes for our clients to choose from. Our provided hose is designed for use with DWV systems to aid to remove wastewater from plumbing fixtures. Our quality examiner checks this Stainless Steel Hose on different quality parameters before dispatching at clients end.

Features:

- Optimum durability

- Robust design

- High endurance

Product details

|

Compression |

2 Heads |

|

Material |

SS |

|

Single Hose Length |

6 m |

|

Application |

Usage |

|

Size |

1/4 inch(DN 6) to 12 inch(DN 300) |

|

Type |

Hydraulic Hose Pipe |

Flexible Solutions for Demanding Applications

Our stainless steel hoses are engineered to handle extreme pressures (up to 215 bar) and high temperatures (-40C to +600C), making them ideal for industrial, chemical, and food & pharma sectors. The flexible, corrugated design allows for easy installation in challenging layouts while maintaining excellent flow and maintaining integrity under pressure.

Superior Material and Customization Options

Choose from a variety of durable end fittingsStainless Steel 304/316, brass, or carbon steelto match your system needs. Custom hose lengths and diameters (6 mm to 300 mm) provide the solutions required for specialized applications. Manufactured using premium AISI 304/316 stainless steel, each hose assures excellent corrosion and fire resistance.

Certified Quality with Reliable Performance

Our hoses comply with international standards (BS 6501 / EN ISO 10380) to ensure consistent quality and safety. Each product undergoes rigorous testing for burst pressure (up to 860 bar) and temperature shock resistance, making them suitable for transporting steam, water, oil, and gases in demanding environments.

FAQs of Stainless Steel Hose:

Q: How can I customize the length and end fittings of a stainless steel hose for my application?

A: You can specify your desired hose length and choose from several end fitting types, such as SS 304/316, brass, or carbon steel. We manufacture hoses tailored to your requirements, ensuring compatibility with your operational setup and connection type (flanged, threaded, or camlock).Q: What are the main benefits of using an annular corrugated stainless steel hose in industrial environments?

A: Annular corrugated hoses provide high flexibility, excellent corrosion resistance, and durability under harsh conditions. They perform reliably with exposure to high pressures and extreme temperatures, minimizing maintenance and replacement costs in industrial settings.Q: When is a stainless steel hose suitable for high-pressure and temperature shock applications?

A: Our stainless steel hoses are designed to operate under pressures up to 215 bar and withstand temperature shocks from -40C to +600C. Their robust design makes them suitable for environments where temperature and pressure can fluctuate suddenly, such as in petrochemical or HVAC systems.Q: Where are these hoses typically used, and which industries benefit most from them?

A: These hoses are widely used in industrial, chemical, petrochemical, HVAC, food processing, and pharmaceutical industries. Their versatility ensures safe transport of steam, water, oil, and gases across demanding and sensitive operational environments.Q: What is the process for manufacturing a stainless steel hose with annular corrugation and stainless steel braid?

A: The hose is formed from premium AISI 304/316 stainless steel by annular corrugation, enhancing flexibility. It is then reinforced with a stainless steel braid, which increases pressure resistance and longevity under mechanical stress.Q: How does the hoses compliance with BS 6501 and EN ISO 10380 impact its reliability and safety?

A: Compliance with these standards confirms that the hoses meet rigorous safety and performance benchmarks, ensuring they are fit for use in critical applications where reliability and operational safety are paramount.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Industrial Hoses' category

|

HYDROFLEX PIPE (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |