Lance Hose for Steel Plant

Product Details:

- Hardness 60-70 Shore A

- Medium Water and Slurry

- Reinforcement High Tensile Steel Wire Braiding

- Shape Round

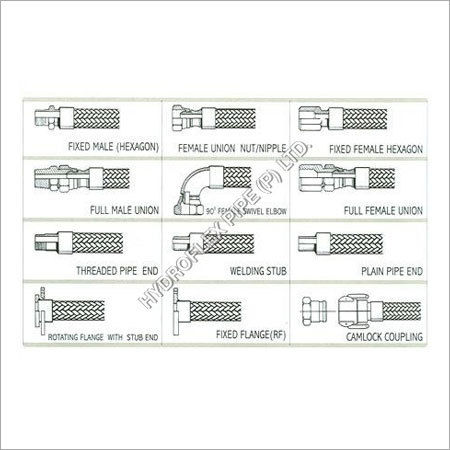

- Connection Type Flanged or Plain End

- Cover Abrasion and Weather Resistant Synthetic Rubber

- Material Other

- Click to View more

Lance Hose for Steel Plant Price And Quantity

- 1000.00 INR/Piece

- 100 Piece

- High

- Yes

- Customizable as per requirement

- Good for Hot and Cold Services

- Black

- Steel Plant Lance Line

- Up to 30 Bar

- MS Flange/Threaded Coupling/As per IS Standard

Lance Hose for Steel Plant Product Specifications

- Round

- Up to 80C Celsius (oC)

- 35 mm to 112 mm Millimeter (mm)

- Up to 10 Bar Bar

- Water and Slurry

- 60-70 Shore A

- High Tensile Steel Wire Braiding

- Flanged or Plain End

- Other

- Abrasion and Weather Resistant Synthetic Rubber

- 25 mm to 100 mm Millimeter (mm)

- High

- Yes

- Customizable as per requirement

- Good for Hot and Cold Services

- Black

- Steel Plant Lance Line

- Up to 30 Bar

- MS Flange/Threaded Coupling/As per IS Standard

Lance Hose for Steel Plant Trade Information

- Cash on Delivery (COD), Cash in Advance (CID), Cheque

- 1000 Piece Per Day

- 1 Days

- All India

Product Description

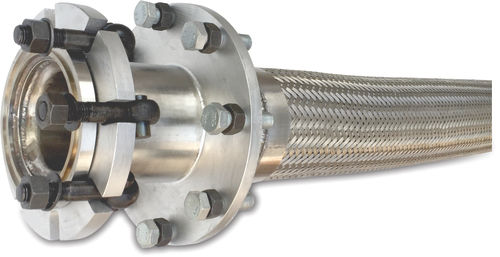

Lance hose has great application in steel plants. We have supplied quality hoses to many steel plants. They show a reliable performance in adverse, hostile conditions. The cleaned, degreased hoses are pressure-sealed and leak-proof. They are utilized with / without inner interlocked liner. There are oxygen and water lance hoses for Steel Plants. The flexible metal hoses are suited for broad temperature range. They make up for thermal expansion too. Some key features include: high physical strength, moisture resistant, fire resistant, longer life, flexible & quick. Resistant to abrasion and damage is other fundamental characteristic.

Product details

|

Head shape |

Round |

|

Usage |

Industrial |

|

Material |

SS |

|

unit Length |

1m - 6m |

|

Nominal Size |

3/4 inch |

|

Single Hose Length |

1m-6m |

Precision-Engineered for Steel Plants

Our lance hoses are specifically designed for steel plant applications, ensuring reliability in harsh, high-pressure environments. The combination of synthetic rubber, steel wire reinforcement, and abrasion-resistant cover offer outstanding performance and long service life, making them the preferred choice for critical lance line operations.

Custom Solutions to Suit Your Needs

We provide customizable options for length, end fittings, and diameter, ensuring that every steel plant project receives a hose tailored to its precise requirements. Our OEM service and adherence to IS standards guarantee compatibility and stress-free integration into existing systems.

FAQs of Lance Hose for Steel Plant:

Q: How is the Lance Hose for Steel Plant used in lance line applications?

A: The Lance Hose is primarily utilized to transfer water or slurry to the lance lines in steel plants. Its robust construction and temperature resistance ensure safe transport of mediums under high-pressure and variable temperature conditions encountered during steel production processes.Q: What are the available customization options for this lance hose?

A: Customers can customize the length, inside and outside diameters (ranging from 25 mm to 100 mm and 35 mm to 112 mm, respectively), end fittings such as MS flange or threaded couplings, and choice of plain or flanged ends. OEM services allow further tweaking to match specific plant requirements.Q: When should I consider replacing my lance hose in the steel plant?

A: Replacement is recommended when you notice reduced flexibility, significant surface wear, leaks, or loss in pressure handling capacity. Regular inspection is vital, especially since the hose operates in hot and abrasive environments, to ensure peak performance and safety.Q: Where can the lance hose be supplied or exported from?

A: We are a reputed distributor, exporter, manufacturer, producer, and supplier based in India, serving domestic and international clients. Our logistical capabilities ensure timely deliveries to steel plants across various regions.Q: What is the process for ordering a customized lance hose?

A: Begin by sharing your specific size, length, connection type, and performance requirements. Our team will recommend suitable configurations and provide a quotation. Upon approval, your hose will be manufactured to order, tested for compliance, and dispatched efficiently.Q: What are the benefits of using this hose in steel plant environments?

A: This hoses abrasion and weather-resistant synthetic rubber cover, high-tensile steel wire reinforcement, and robust end fittings provide high durability, flexibility, and safety. Its ability to withstand high pressures and temperatures makes it ideal for demanding steel plant applications, minimizing downtime and maintenance costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Industrial Hoses' category

|

HYDROFLEX PIPE (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |