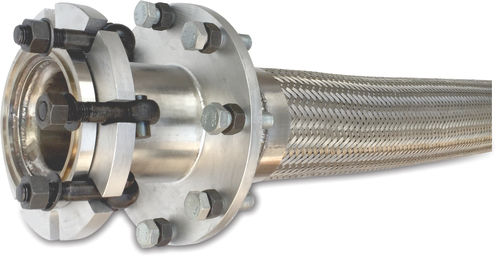

Corrugated Hoses

Product Details:

- Cover Stainless Steel / PTFE

- Hardness Flexible (Corrugated Structure)

- Medium Gas, Water, Steam, Oil, Chemicals

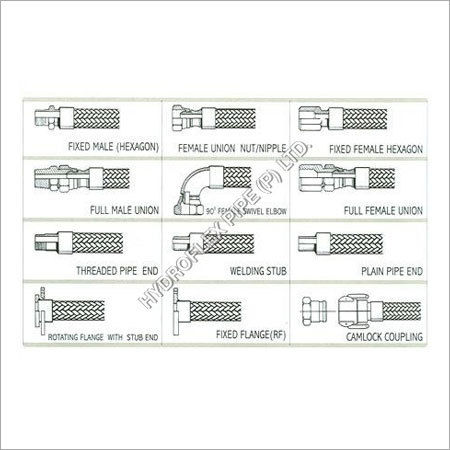

- Connection Type Flanged, Threaded, Welded, Quick Couplings

- Shape Round, Corrugated

- Reinforcement Stainless Steel Strip or Wire Braiding

- Material Stainless Steel (SS304, SS316, SS316L), PTFE

- Click to View more

Corrugated Hoses Price And Quantity

- 100 Piece

- 300.00 - 1000.00 INR/Unit

Corrugated Hoses Product Specifications

- Stainless Steel (SS304, SS316, SS316L), PTFE

- 6 mm to 350 mm

- Varies as per design

- Stainless Steel / PTFE

- Round, Corrugated

- Gas, Water, Steam, Oil, Chemicals

- Flexible (Corrugated Structure)

- Flanged, Threaded, Welded, Quick Couplings

- Stainless Steel Strip or Wire Braiding

- Up to 200 bar

Corrugated Hoses Trade Information

- 1000 Piece Per Day

- 1 Days

Product Description

Our company is a reckoned entity engaged in offering an exclusive range of Corrugated Hoses. Owing to their high flexibility, resistance to corrosion and durability, our hoses find application in chemical, pharmaceutical, cement and petrochemical industries. High quality raw materials are used to manufacture these steel hoses. In addition, as a quality driven organization, Corrugated Hoses offered by us are assured to be at par with international standards.

Product details

|

Testing Pressure |

600 Bar |

|

Thickness |

2-5 mm |

|

Usage |

Transport water, Weak Acid Weak Base Liquid |

|

Working Temperature |

-30 Deg. C-120 Deg. C |

|

Size |

4 inch |

|

Single Hose Length |

1m-6m |

High Pressure Flexible Hose Assemblies for Gases Specification:

- Hose Material: AISI 316L (DIN EN 1.4404)

- Braid Material: AISI 304 (DIN EN 1.4301)/ AlS1316L (DIN EN 1.4404)

- Braid Type: Double Wire Braided

- Hose Size: DN 6 (1/4 NB /6.4 mm ID)

- Hose Length Overall: 500 mm, 750 mm, 1000 mm, 1500 mm, 2000 mm, 3000 mm

- End Fittings: 1/4 NPT Female Fixed/ Suitable for Gas Cylinders Valve

- End Fittings Material: AISI 316L (DIN EN 1.4404)

- Over Wire Rope: AISI 304 (D1VN 1.4301) /AISI 316L (DIN EN 1.4404)

- Max. Working Pressure: 400 Bar 20 Degree C

- Testing Pressure: 600 Bar

- Burst Pressure: 1200 Bar

Robust Construction and Versatile Applications

Manufactured from premium SS304, SS316, SS316L, or PTFE, corrugated hoses offer outstanding durability and corrosion resistance. Their flexible structure accommodates high-pressure requirements and supports various media, including chemicals and steam. Catering to the industrial sector, these hoses reliably perform in demanding environments, providing safe and efficient fluid transfer for a wide range of purposes.

Customizable Design and Connections

Corrugated hoses are available in inside diameters from 6 mm to 350 mm, with the outside diameter tailored to specific project needs. The hoses offer flexible connection optionsflanged, threaded, welded, or quick couplingsensuring seamless integration into diverse piping systems. This customization ensures users receive solutions best suited for their operational requirements.

FAQs of Corrugated Hoses:

Q: How are corrugated hoses installed for different connection types?

A: Corrugated hoses can be installed using flanged, threaded, welded, or quick coupling connections. The choice depends on system requirements and available interfaces, allowing easy integration into existing setups or new installations.Q: What media can be safely transported using these corrugated hoses?

A: These hoses safely carry gases, water, steam, oil, and chemicals due to their robust stainless steel or PTFE construction and reinforced design, making them suitable for a variety of industrial applications.Q: When should stainless steel reinforcement be used in hose selection?

A: Stainless steel reinforcement, such as wire braiding or strip, should be used when higher pressure ratings or additional mechanical protection are required, particularly for demanding processes involving harsh media or pressure fluctuations.Q: Where are corrugated hoses typically applied in industry?

A: Corrugated hoses are commonly used in chemical, petrochemical, power generation, oil & gas, and water treatment industries across India, wherever flexible, high-pressure connections are essential for safe and efficient media transfer.Q: What benefits do corrugated hoses offer over traditional rigid piping?

A: Corrugated hoses offer greater flexibility, vibration absorption, and thermal expansion accommodation than rigid pipes. Their corrosion resistance and pressure handling capabilities also enhance reliability and reduce maintenance.Q: How does the manufacturing process ensure hose quality and pressure resistance?

A: These hoses are manufactured using precision forming and reinforcement techniques, utilizing premium stainless steel or PTFE materials to achieve desired flexibility while maintaining superior pressure and chemical resistance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Industrial Hoses' category

|

HYDROFLEX PIPE (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |