Stainless Steel Hose Assembly

Product Details:

- Hardness Annealed

- Application Steam, Chemical, Oil, Gas transfer

- Working Presssure Up to 300 bar

- Use Industrial Fluid Transfer

- Product Type Hose Assembly

- Material Stainless Steel (SS 304/316)

- Finish Polished

- Click to View more

Stainless Steel Hose Assembly Price And Quantity

- 200.00 - 1500.00 INR/Piece

- 100 , , Piece

Stainless Steel Hose Assembly Product Specifications

- -200C to 700C

- Hose Assembly

- Flanged, Threaded or Welded ends

- Up to 300 bar

- Polished

- Customizable as per requirement

- Industrial Fluid Transfer

- Flexible stainless steel braid

- Corrugated stainless steel

- Steam, Chemical, Oil, Gas transfer

- Annealed

- Stainless Steel (SS 304/316)

Stainless Steel Hose Assembly Trade Information

- 1000 , , Piece Per Day

- 1 Days

Product Description

Stainless steel hose assemblies are utilized in a range of industrial activities. They are practical in chemical processing, petroleum applications, vibration absorption, and other industrial. These are outstanding flexible metal hoses or metal hose assemblies. Also, there are several sizes, types and configurations. We meet demanding specifications as well as codes. Our stainless steel hose assemblies are designed to withstand the severeness of actual conditions. They deliver efficiency, reliability and long service life. Some other applications include: furnace cooling, oxygen services, natural gas, HVAC offsets, etc.

| Specification: | |

| Hose Material | AISI 321 (DIN EN 1.4541) / AISI 316L (DIN EN 1.4404) |

| Braid Material | AISI 304 (DIN EN 1.4301) / AISI 316L (DIN EN 1.4404) |

| Braid Type | Single wire braid / Double wire braid for higher pressure |

| Hose Size | DN 6 (1/4" NB) to DN 100 (4 NB) |

| Hose Length Overall | 10, 11, 12, 13, 14, 15, 16, 18 |

| End Fittings | Male fix type SCH 40 pipe threads BSP/BSPT/ NPT threads, |

| End Fittings Material | CS / AISI 304 (DIN EN 1.4301) / AISI 316L (DIN EN 1.4404) |

| Working Pressure | 1800 PSI ( 124 BAR ) @ 20 C to 232 PSI ( 16 BAR ) @ 20 C |

| Offset Motion Static | 3/4" to 1/4" |

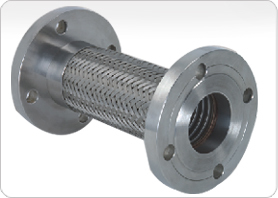

Stainless Steel Braided Flexible Pump Connectors Flange End

| Specification | |

| Hose Material | AISI 321 (DIN EN 1.4541) / AISI 316L (DIN EN 1.4404) |

| Braid Material | AISI 304 (DIN EN 1.4301) / AISI 316L (DIN EN 1.4404) |

| Braid Type | Single wire braid / Double wire braid for higher pressure |

| Hose Size | DN 15 (" NB ) To DN 300 ( 12 NB ) |

| Hose Length Overall | 8, 9, 10, 11, 12, 14, 15, 16, 18 |

| End Fittings | Fixed Flange / Swivel Flange as per ANSI B16.5 150#, 300# / DIN PN 10 / PN 16 / PN 40 |

| End Fittings Material | CS A105 / AISI 304 (DIN EN 1.4301) A182 / AISI 316L |

| Working Pressure | 507 PSI ( 35 BAR ) @ 20 C to 160 PSI ( 11 BAR ) @ 20 C |

| Offset Motion Static | 3/4" to 1/4" |

Exceptional Flexibility and Strength

Designed with annular or helical corrugations and a flexible stainless steel braid cover, these hose assemblies ensure superior flexibility while maintaining excellent strength. Their low minimum bend radius, depending on the tube ID, facilitates seamless integration in challenging layouts without risking hose integrity or performance.

Zero Leakage and High Pressure Tolerance

Engineered to meet strict BS 6501 and ASTM/ISO standards, our stainless steel hoses deliver zero leakage under rated pressure and can withstand burst pressures up to 600 bar. These robust assemblies are trusted for critical fluid transfer applications, ensuring operational safety and efficiency even in the most demanding environments.

Tailored Solutions for Industrial Applications

Whether you need specific lengths, customized end connections, or specialized packaging, we provide fully customizable solutions. The hoses are suitable for high- and low-temperature environments, efficiently handling fluids like steam, chemicals, oil, and gases, making them an indispensable choice for diverse industrial sectors.

FAQs of Stainless Steel Hose Assembly:

Q: How does the stainless steel hose assembly ensure leak-free operation under high pressure?

A: The hose assembly is designed to deliver zero leakage under rated pressure, thanks to precise engineering, robust corrugated stainless steel tubing, and secure end connections. It undergoes rigorous pressure testing and adheres to international quality standards such as BS 6501 and relevant ASTM/ISO requirements to guarantee reliable, leak-free performance even at pressures up to 300 bar.Q: What are the main industrial uses of this stainless steel hose assembly?

A: This hose assembly is primarily used for the safe transfer of steam, chemicals, oil, and gases in industrial settings. Its versatility, temperature tolerance, and corrosion resistance make it suitable for refineries, chemical plants, HVAC, power generation, and other fluid transfer operations.Q: When should I choose a stainless steel braided hose with annular or helical corrugation?

A: Annular corrugated hoses are best suited for applications requiring high flexibility and vibration resistance, while helical types are preferred for specific applications that need fluid flow to follow the corrugation spiral. Selection depends on your applications pressure, flexibility, and vibration needsour team can guide you to the optimal design based on your requirements.Q: Where can these hose assemblies be installed and used safely?

A: They can be safely installed in a wide variety of industrial environments, from chemical plants to oil and gas facilities, as well as steam systems, and manufacturing lines. Their excellent corrosion resistance and broad temperature range (-200C to 700C) mean they perform reliably in harsh and demanding settings.Q: What customization options are available for these hose assemblies?

A: We offer a range of customizable features, including various inner and outer diameters (6 mm300 mm and 10 mm320 mm), lengths, end connection types (flanged, threaded, or welded), packing methods, and material choices (SS 304/316 or carbon steel ends) to precisely match your project specifications.Q: How does the product compare to conventional rubber or plastic hoses?

A: Stainless steel hose assemblies provide far superior durability, higher operating temperatures, greater pressure resistance, and outstanding corrosion protection compared to rubber or plastic hoses. This results in a longer service life, reduced maintenance, and enhanced safety in critical fluid transfer applications.Q: What are the benefits of using hoses conforming to BS 6501 and international standards?

A: Compliance with BS 6501 and ASTM/ISO standards assures consistent product quality, safety, and suitability for demanding industrial applications. Users benefit from internationally recognized certifications, ensuring the hose assemblies meet or exceed required specifications for pressure, leak resistance, and mechanical strength.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

HYDROFLEX PIPE (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |